Drone Maintenance Plan V1

Introduction

After you fly your drone for any number of flight hours[1], you will face the issue of aircraft maintenance. As a remote pilot, you should have a strategy for how to handle maintenance, even if your choice is to let it ride and do nothing. That is still a strategy, although not a good one because it exposes you to unnecessary risk. The FAA[2] has a strong opinion on unmanned aircraft vehicle (UAV) maintenance that we will review. The review alone is not quite enough. As a remote pilot, you must internalize your approach to this workload and develop an understanding of the FAA’s rationale. You also want to keep your drone in the air, right?!

My Experience

Because I have a small budget, my own maintenance experience initially started with an ad hoc approach. To get the best results from this approach, I created a rule for myself that I will inspect the drone before and after every flight as well as upon returning to my hanger. My rationale is that I always want to have the drone in a flight-ready state. Upon arriving at home base upon completion of an assignment, the following tasks are conducted:

- Recharge all drone main batteries (3x)

- Replace SD card with a new one

- Check state of propellers (replace as needed)

- Purchase more propellers if needed (minimum 4 for complete replacement)

- Clean motors and arms

- Check gimbal and camera

- Repack drone backpack for next assignment

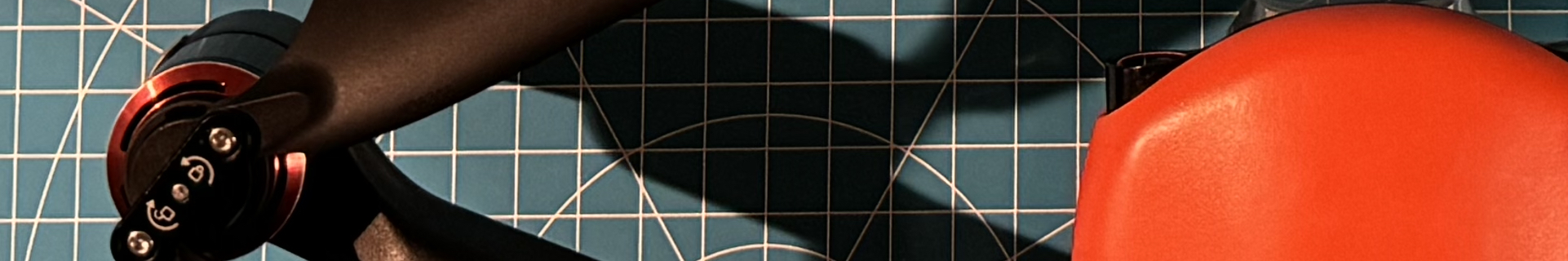

If anything irregular is found during the inspection at home and maintenance is required, then parts are ordered and work to fix the issue will begin when those parts arrive. Over time, I have created a workspace for drone maintenance. I call it my hangar or maintenance bay, which sounds big and high-tech, but really, it’s an old high school science table, a bright blue 24 inch by 36 inch cutting mat and movable overhead lighting. The most important aspect of all this is that I have a dedicated workspace clear of unrelated objects. I did not create maintenance logs but relied on me being the sole remote pilot with a single drone which meant all drone related events originated solely from my actions.

When I was piloting a dji[3] drone, this approach seemed to work well. Amazon and dji have a very healthy supply chain and I could count on getting necessary replacement parts in one to three days. However, my dji flying days did not last long due to coastlines and bad math: I could not take off in my own backyard. I live in a coastal town and to cut a long story short the dji geo-fenced no-fly zone for the body of water next to my town includes half of my town and my home. I could fly the drone up to about 10 ft then it would land itself. I switched to an Autel[4] drone, to get around the geofencing no-fly issue. It is with this Autel drone I have spent nearly all of my time flying.

Grounded!

After two years of flying I finally experienced an incident that grounded me for over three weeks. That grounding is the reason I have written this article and have also revised my approach to maintenance. What happened, you ask? The incident itself was small: a stress fracture snapped while I was placing the drone in the backpack as I was about to leave for an assignment. The front left landing foot had a stress facture that snapped along the foot’s securing holes, leaving the foot misaligned and floating, yet still attached to the arm. No problem, I thought, since this is a maintenance task I have conducted more than once on a dji mavic drone. Total time for the work is less than 5 minutes if necessary replacement parts are in hand.

Figure 1: Removal of broken part exposes the radio antenna

Figure 2: Broken part with stress fracture and plastic crumbs

I’ll jump on Amazon and order these parts, I thought to myself. Get the part and do the work in a day or two, I anticipated. Well, no available part means no maintenance. It slowly dawned on me, I was grounded![5]. That’s it, I could not fly until I carry out maintenance on my drone. I found out that the retail supply chain for Autel is not as robust as it is for the dji; I could not find the part new. Thinking of other sources for the part, I checked out 3D printing and found a printable[6] and began honing my online searches. Eventually eBay panned out, and I was able to purchase a number of the parts. I was also able to get the 3D printable made, but the quality of the printer very much affected the output. The resolution was not good enough. Interestingly, printing the part cost $0.60!

Ok, that was a slew of logistical details I did not really care to repeat. I now know drone companies offer enterprise services, and if that’s within your reach, go for it! But I am an independent remote pilot with a limited budget. This is a position I actually like because it generally means that purchasing choices need to backed by rational decisions and a commitment to a plan, however loose. I am not too big to fail.

Observations

I dislike spending my flight time on logistics! That and not actually being out there flying were the biggest setbacks. And I certainly did not like being grounded along with the uncertainty of being able to purchase the required part(s).

3D print looks promising for prototyping drone parts. I need to understand 3D print materials and their tensile strength.

Drone pre-flight and post-flight inspections are a critical component of the flight plan and drone maintenance. However, it is entirely possible that an inspection may not reveal all damage. For example, hairline cracks in the drone body shell can be easily missed in bad light.

As an owner of a consumer/retail drone, the supply chain is outside your and my control. To some degree the bigger, the better here. For example dji is one of the biggest drone companies out there so there is a health secondary market for parts.

I need to fully understand what this means for my relationship with the drone manufacturer and how I should stay up to date on a drone’s development lifecycle.

FAA Regulation

The FAA’s position is made clear in Chapter 7 of the Advisory Circular 107-2 document (AC_107-2.pdf). Yup, there’s a whole chapter called sUAS Maintenance and Inspection. It’s a great sign that the title includes the word inspection as I believe it is a foundational action to a good maintenance plan. It makes me happy that the FAA and I are in alignment.

7.2 Maintenance. sUAS maintenance includes scheduled and unscheduled overhaul, repair,

inspection, modification, replacement, and system software upgrades of the sUAS and its

components necessary for flight. Whenever possible, the operator should maintain the

sUAS and its components in accordance with manufacturer's instructions. The aircraft

manufacturer may provide the maintenance program, or, if one is not provided, the

applicant may choose to develop one. See paragraph 7.3.5 for suggested benefits of

recordkeeping.

There’s more, so it’s worth reading the document (AC_107-2.pdf) even if it’s a refresher.

Conclusion

I need to update and formalize my maintenance plan and have a higher frequency of check-ins with the governing body - the FAA[2]

There are elements of my maintenance plan that are working.

- Drone Inspections (1 pre-flight and 2 post-flight)

- Cleaning the drone after every assignment on arrival at home

- Prepare drone for next assignment at the end of every assignment

- The concept of flight readiness[7] is the keystone of my informal maintenance plan

Overall I am pleased with the first iteration of my maintenance strategy. I would not call it a plan yet. Another iteration is required but the path forward is clear - more alignment with the FAA’s position. Internalization of your maintenance strategy is a good, but a plan, documentation, and logs are even better!

Keep Flying…

References

- https://en.wikipedia.org/wiki/Flight_time

- https://www.faa.gov/uas

- https://store.dji.com

- https://www.autelpilot.com/?variant=40329791176750

- https://www.caa.co.uk/commercial-industry/aircraft/airworthiness/grounded-aircraft/

- https://www.printables.com/model/228581-autel-evo-2-2-pro-rear-landing-leg

- https://www.ecfr.gov/current/title-14/chapter-III/subchapter-C/part-415/subpart-C/section-415.37